|

The ball is (even) rounder

Adidas is the leading international brand in the soccer market, and not by chance. Since 1970, Adidas has been developing the new official soccer ball of the Mondial games every four years - the soccer world cup. Before Adidas embarked upon this enterprise, the soccer ball was heavy, brown, and bulky. The innovations that Adidas introduced over the years were design oriented and functional, and changed the sport unrecognizably.

The 1970 (Mexico) ball was made

entirely of leather like its predecessors, but was sewn

from five black pentagons and twenty white hexagons,

which gave it a more attractive design and a rounder

surface area (that made it possible to kick it further

and more accurately). In 1974 (Germany) the ball's

colors were changed, and in 1978 (Argentina) it was sewn

from 20 panels with groups of three, making it seem as

if it were made of 12 identical circles, and it was more

durable to weather. In 1982 (Spain) a waterproof coating

was added to the ball (and since then the ball is not as

heavy when it rains).

In 1986 (Mexico once again) a

soccer ball from synthetic leather was introduced for

the first time (more durable and absorbs less moisture).

In 1990 (Italy) an internal polyurethane layer was

added, and for the first time the ball was completely

water resistant, and faster than ever. In 1994 (United

States) the polyurethane layer was improved and it made

the ball springier (softer to the touch, easier to

control, and much faster when kicked). In 1998 (France)

a soccer ball made of three colors was introduced for

the first time, and small gas bubbles trapped in the

internal layer improved the ball's durability and

precision. In 2002 (Japan/Korea) a change in the

segments the ball was sewn from and the addition of

layers increased the ball's precision while airborne.

The 2006 Finals' ball (Germany,

this month) will reach the shelves on the 10th of

December of this year, and is expected to be the best

sold ball in history. It contains 14 parts with an

innovative design, whose sewing together decreased the

number of stitches by 15% and the quantity of points

where 3 parts touch each other by 60%. The result is a

ball that is rounder than ever before, smooth, and

easier to control. In addition, the parts are joined by

an innovative technology that uses warm adhesion, and

therefore the ball absorbs less than 0.1% water

(compared to the FIFA standard that permits 10%

absorption). A dry soccer ball flies even faster and

higher through the air.

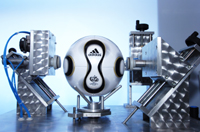

Additional tests, conducted

with typical German precision show that the new soccer

ball is even more accurate by 30% compared to other

esteemed balls (when the ones kicking are… robots), its

diameters (which are measured in 10 different spots)

differ only by a quarter of a centimeter (in contrast to

the standard - a whole centimeter), the weight of the

new balls differ only by 3 grams (when the permitted

standard is 25 grams), and the difference between the

ball's various bounces when it is tossed from a height

of 2 meters is only up to 2 cm (the permitted standard

is 10 cm). Without a doubt this is the best soccer ball

that has ever been manufactured: it's faster, rounder,

more precise, and easier to control. Maybe this is why

the Brazilians have lost their relative advantage?

|